Meet Ali and Matt

This week we feature two more Creators and Innovators who will inspire you. If you know someone who you think should be a part of this series highlighting all of the many gifts we have in our congregation, please feel free to nominate them here!

Meet the Queen of Clean - Alison Main. Since joining St. Barnabas six years ago with her husband, Zig, they have become an inspiration to us through their dedication and enthusiasm for worship and music. You can find Ali in the choir loft raising her voice with the angels and archangels as well as a regular Lector at the 8am service. She has served on the Vestry and volunteers her insight, calming voice and gentle spirit into many of our small groups.

After graduating from the University of Oxford, Ali began working in England and eventually was called to the states to work for P&G here in Cincinnati where she has risen to the position of Vice President, R&D.

A Global R&D leader with 20+ years’ experience creating winning innovation across multiple consumer goods categories, including detergents, paper products, batteries, over the counter drugs and dietary supplements. A strategic, results-oriented leader of geographically dispersed teams, with a demonstrated track record of integrating consumer insights, breakthrough technologies and manufacturing processes to deliver a strong pipeline of revenue-building new products and platforms. An outstanding organizational leader with extensive experience of building, developing and inspiring global multi-functional teams; known for creating a healthy culture that facilitates innovation, partnership, and clear communication. (credit: LinkedIn)

When asked if she would share her story she jumped right in and said, “Yes, I’m game. I’m an inventor of Cascade Actionpacs (dishwasher detergent), which came before Tide pods. I was a Section Head in R&D and was part of a team of outstanding engineers."

According to Patent 20050061703, Ali's invention is a water-soluble multi-compartment pouch adapted to fit the dishwasher dispenser and to deliver product into the pre-wash, main wash and/or post-rinse cycles of the dishwashing machine.

"It's a fun story and the reason why P&G asked me to relocate to the US. We first manufactured actionpacs at P&G's Corporate Engineering and Technology Lab in West Chester, reusing parts from a diaper line. There were many times when we wondered if it was going to be physically possible! It was so successful that P&G went on to build a couple of manufacturing lines in France. The first time the machine ran for a whole minute we had pouches pouring off the line, overflowing the collection bin and all over the floor. We literally ran up and down the corridor celebrating! I even had one of the first pouches off the French line cased in an acrylic block for preservation....and the rest is history. Happy memories!!

It's incredible that Ali's invention impacted entire product lines of cleaning products which make our lives cleaner and easier!

The next time you see Ali, grab a cup at coffee hour and ask her to share one of her many stories about how she changed the world of cleaning products. Congratulations Ali, we’re so glad you are a part of our Creative, Innovative and Inspiring St. Barnabas Community.

Learn more about Ali's amazing journey.

&

Matt Krumanaker and his family joined St. Barnabas in 2015. They have become involved in all aspects of St. B life including Matt serving on the Vestry for the last 3 years, his wife, Diane, providing veterinary support to many of our members through Montgomery Animal Hospital and don't forget the bread baking for Sunday services which is something Matt enjoys doing with his daughters. If you have a chance to try their amazing brownies at the next carry-in dinner….don’t miss out! They are the best!

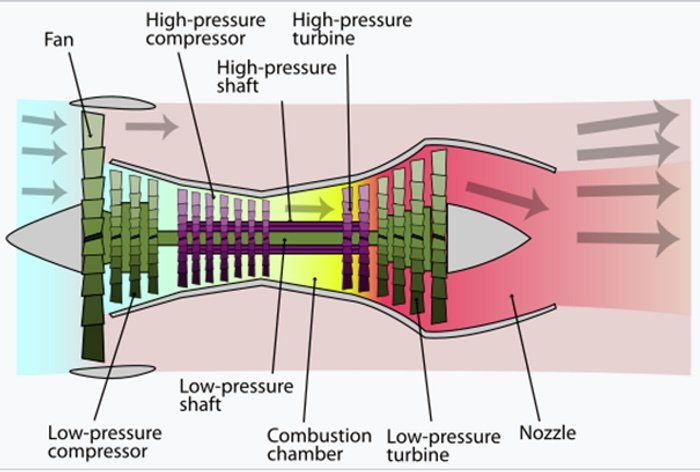

When Matt isn’t walking the dog, fixing bicycles or riding his bike throughout Ohio, he spends his days as a staff engineer for General Electric’s Aviation Division. Since 2002, Matt has worked to create innovative ways to make our air travel more efficient

“I’ve spent most of my career designing high pressure turbine blades and vanes with the goal of helping make aircraft engines more fuel efficient. The engines that power the Boeing 737 Max and the Boeing 777X have parts that I helped design. To gain fuel efficiency, modern airplane engines have been designed to operate at higher temperatures than previous engines.

The parts I help design are made of nickel alloys capable of operating at bulk temperatures of 1600 to 1800 degrees Fahrenheit. The challenge is the air temperature around large portions of these parts are 2500 to 3200 degrees Fahrenheit during takeoff and climb, so efficiently cooling these parts is paramount to overall engine durability and efficiency.”

"I think I have 9 patents at this point with more in the works. My favorite one so far was US-20170234137-A1 which is a novel way of ejecting air out the back of turbine blade or vane that improves efficiency, provides better cooling , and in theory will be easier to manufacture. And it's not very often that I make something easier to manufacture so that's why I like it."

We are so glad that Matt's knowledge and drive for new innovation in the skies continues to keep us safely traveling the world. The next time you see Matt at St. B congratulate him on making sure your plane is working as efficiently as possible. Thanks Matt!